Gorenje

Gorenje Group is one of the leading European home appliance manufacturers with a history spanning more than 60 years. Gorenje 'Products and Services for Home' produces and sells major household appliances, small domestic appliances, kitchen furniture, and HVAC (heating, ventilation, and air conditioning). Its global presence is built on two brands: Gorenje, which includes the entire range of home products of the upper-mid price range; and ASKO, which is positioned as a global premium brand.

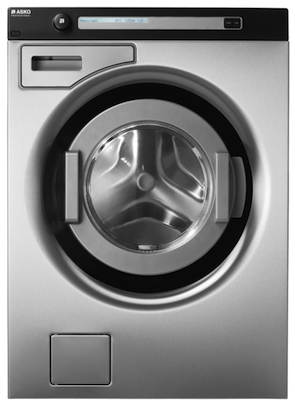

During the ResCoM project, Gorenje explored the business case for, and associated challenges with ‘GoRent’, a potential new service model for its ASKO washing machines. The model aims to greatly extend product use while allowing additional revenue to be generated with less material. GoRent offers a leasing model for both domestic customers and the commercial market (e.g. laundrettes, hotels and cruise ships). Washing machines are leased to three market segments, being cascaded through to the next segment over time. Each washing machine will start as premium - a new product with the latest design; it will then be refurbished and offered as economy; and finally offered as budget - a used economy product refurbished for a second time. After this, Gorenje takes back the materials for recycling.

Outcomes of the ResCoM pilot

By participating in the ResCoM project, Gorenje was able to gain a number of insights into the challenges of pursuing the GoRent business model, providing a clearer direction on the best way forward. The ResCoM Circular Pathfinder was used as a starting point for demonstrating the potential of the circular business model to non-technical staff at Gorenje. The tool also confirmed that the characteristics of the GoRent proposition are particularly suited to the circular pathways of upgrading, refurbishment and recycling.

A major challenge to address in offering GoRent was that the continuing involvement of the company means that service and spare parts need to be offered over a much longer time period than they are currently. This means that Gorenje either needs to keep surplus stock or manufacture parts on demand. Applying the ResCoM Part Planning and Multiple Lifecycle Product Design tools, an effective modular design strategy was created to support the interchangeability of parts between successive design generations. This enabled Gorenje to increase product variety with fewer unique components and to reduce design and manufacturing complexity, as each component can be designed and manufactured independently. It also allows Gorenje to introduce new product variants faster into the market and plan multiple lifecycles of products in a pragmatic manner.

An additional challenge highlighted during the pilot was that the cultural change associated with an organisation shifting from production to service provision needs to be carefully considered and managed. The ResCoM tools were used to demonstrate the potential value gain to the management team, and succeeded in broadening the entire organisation’s understanding of the concept of a circular economy, beyond the preconception of ‘recycling’. The Gorenje ResCoM partners were able to demonstrate to the rest of the organisation the value in specifying more durable materials and components, not only to create long-lasting products but also to increase customer satisfaction by offering high-quality products. Additionally, testing the ResCoM tools in a cross-department workshop created a better understanding between team members working on different aspects of the product.

View the platform and tools >>

The ResCoM Circularity Calculator and the MI:Web BoM Analyser helped the product designers understand how design decisions influence circularity, and were used to compare the carbon footprint of different material choices over several use cycles. The Analytical Tool was used to compare the performance of the linear conventional business model with that of potential closed-loop scenarios, and revealed that to make the GoRent model a success, additional costs would need to be minimised, to avoid missing out on the additional value captured through the new model. These costs include reverse logistics, customer care and collecting customer payments, and the costs of repairing and remanufacturing products.

The ResCoM Multimethod Simulation Tool enabled Gorenje to explore the long-term economic and environmental performance of the GoRent model in different scenarios in comparison to their current linear business. The tool, among other things, highlighted that to maximise the performance and to fulfil the demand of the economy and the budget segment, Gorenje needs to maintain an inventory of remanufactured washing machines when launching the GoRent model.

Going forwards

ResCoM provided a first phase analysis on how to create a feasible business case for GoRent. The next planned phase is to undertake a market pilot with around 350 washing machines across four European countries. Taking forward the insights gained from ResCoM, the research during this next phase will have two aims. First, Gorenje will explore how to make maintenance costs predictable and hence easier to minimise. Second, it will explore ways of bringing maintenance in-house to reduce costs, as well as addressing non-technical barriers such as non-paying customers.

Looking ahead, Gorenje is exploring ‘smart’ washing machines that can predict in advance when machines might break down or require maintenance and alert Gorenje. This will provide a more seamless service for customers and help better organise maintenance operations, thus reducing costs. Smart washing machines could also allow Gorenje to explore further circular business models such as ‘pay per use’, thereby opening up new potential revenue streams and even greater choice for customers.